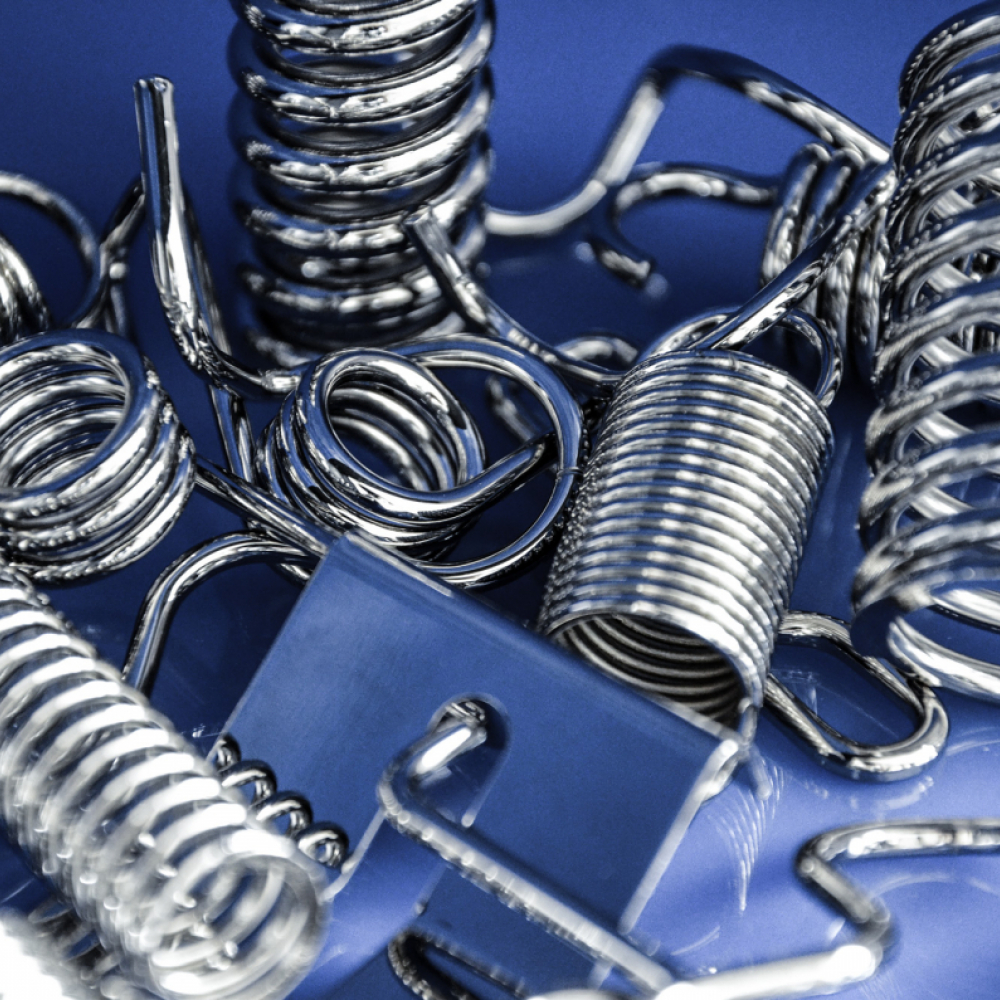

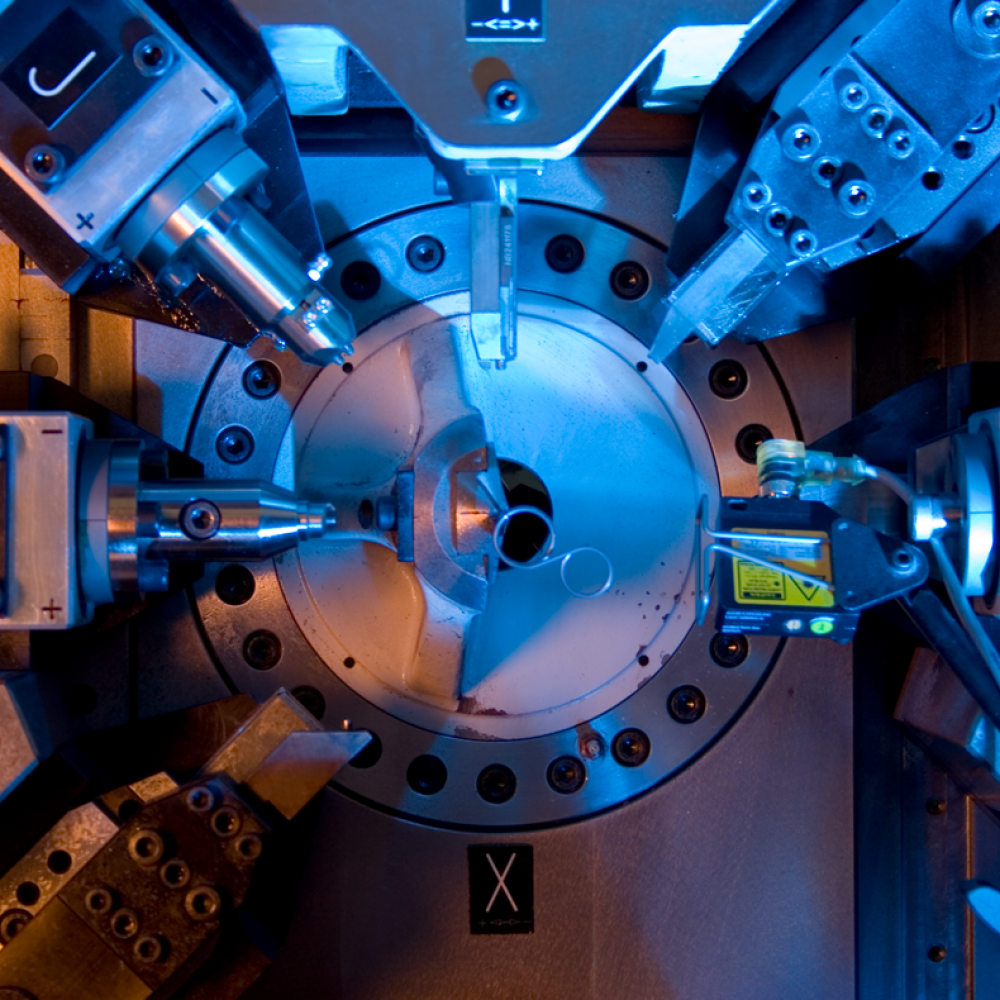

Engineering

We are happy to advise you – in terms of design, material selection and your feasibility study. We carry out corresponding spring calculations and tests in accordance with your specifications, or produce articles based on your technical specifications, draft or sample.